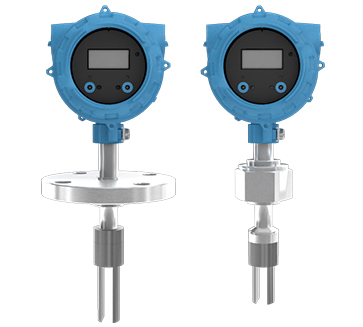

Compact Density Meter

Retrofit Capabilites

A drop-in replacement option has the same face-to-face dimensions as the Micro Motion 7835 and 7845 liquid density meters.

Thermal Insulation

A thermally insulating jacket provides temperature and measurement stability and helps reduce process and environmental impacts.

Tube Vibration

Dual, parallel tubes vibrate at their natural frequency, creating a base line for density measurement.

Density Measurement

The natural frequency changes with the density of the liquid inside the tubes. Changes are converted into density readings using meter calibration coefficients.

Flow Rate Indication (Velocity)

Measurement of the twist in the vibrating tubes gives an indication of the liquid flow rate (velocity), ensuring sample integrity.

Application Configurations

The meter can be configured to measure density, referred density, concentration [such as for oBrix, oBaume, oPlato, % Alcohol by Volume (ABV)] and a variety of other parameters.

Local Display and Compatibility

The meter supports an integral transmitter with a local operating interface, and multiple protocols for connection to DCS, PLC and flow computers.

Diagnostics

Known Density Verification (KDV) confirms the meter health and can identify installation issues.