Your power generation facilities were designed to deliver consistent load profiles and handle routine peaks in demand. But the increased demand for renewable energy and the availability of inexpensive natural gas have forced a change in the way you operate. Ensuring a constant grid supply means increased cycling, which can lead to increased unit heat rates and unplanned shutdowns. Your equipment, budgets, and plant personnel are increasingly challenged to meet your commitment to deliver grid demand. Read more

|

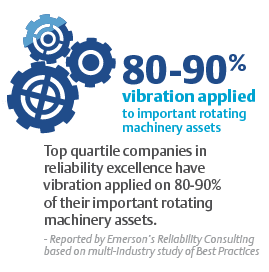

When operators can see the impacts of changing loads on equipment performance, they can make informed decision. That’s why Emerson’s monitoring solutions for critical equipment can be integrated into DCS, including Ovation and DeltaV digital control systems. Varying loads and unexpected peaks in demand takes its toll on your equipment. And fixing the same problems on the same machines time and again can put significant stress on your O&M budget. Like other best-in-class facilities, you need to invest in proven technologies that focus your resources on the right equipment at the right time and fix the root cause of the problem. Emerson offers the services and solutions that curtail unnecessary costs and reduce your spares inventory. No one knows your production assets better than the team that works with them every day. When they retire or move to other positions, what happens to that tribal knowledge? By partnering with Emerson, you’ll tap into resources experienced in building expertise within your team. |